Design for Manufacture (DFM): A Practical Guide

Design for Manufacture (DFM): A Practical Guide

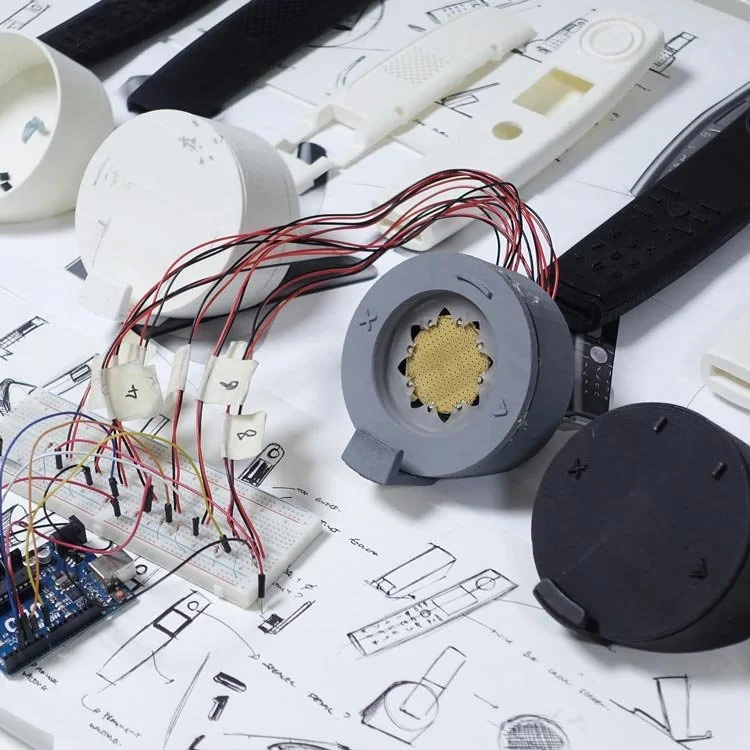

Design for Manufacture (DFM) is the process of designing products so they can be manufactured reliably, cost-effectively, and at scale. It ensures that design decisions consider real manufacturing constraints from the earliest stages of development.

At Alloy, DFM is integrated into the design process — not treated as a late-stage fix.

What Is Design for Manufacture (DFM)?

DFM is about designing products with manufacturing in mind from day one.

It considers:

Materials and processes

Assembly methods

Tolerances and part complexity

Tooling constraints

Cost and yield

DFM ensures that what’s designed can actually be built — repeatedly and profitably.

Why DFM Matters

Many products fail or stall because DFM is applied too late.

Without proper DFM:

Designs need rework during tooling

Costs increase unexpectedly

Quality becomes inconsistent

Launch timelines slip

Good DFM reduces risk before money is locked into production.

When DFM Should Happen

DFM should not be a final checklist.

The most effective DFM happens:

During concept development

Throughout detailed design

Before prototyping decisions are locked

Prior to tooling and supplier commitment

Early DFM leads to better design decisions — not compromises.

What DFM Typically Covers

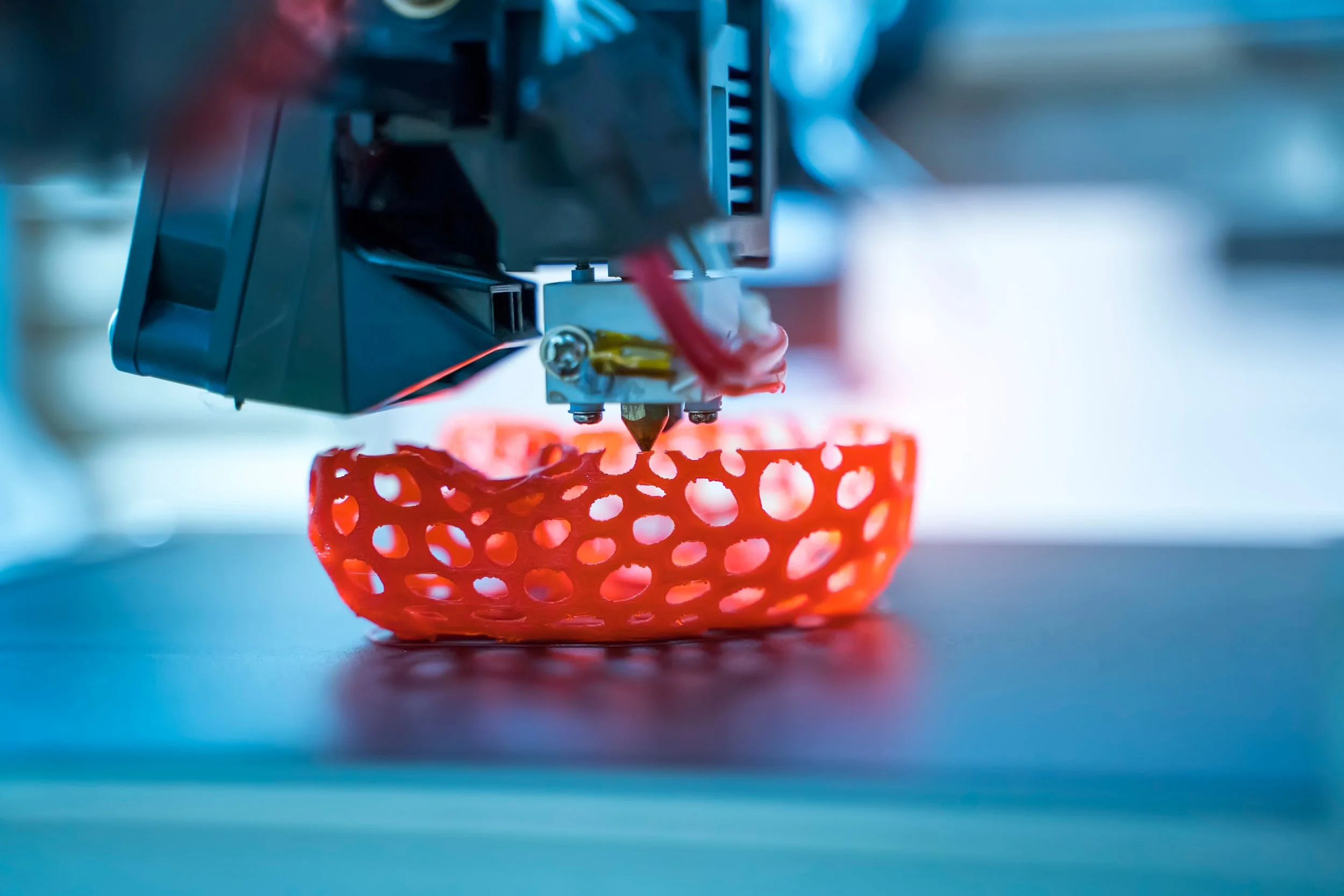

Materials & Processes

Choosing materials that suit:

Performance requirements

Available manufacturing processes

Target cost and volume

Tolerances & Fit

Over-tight tolerances increase cost and scrap.

DFM balances precision with manufacturability.

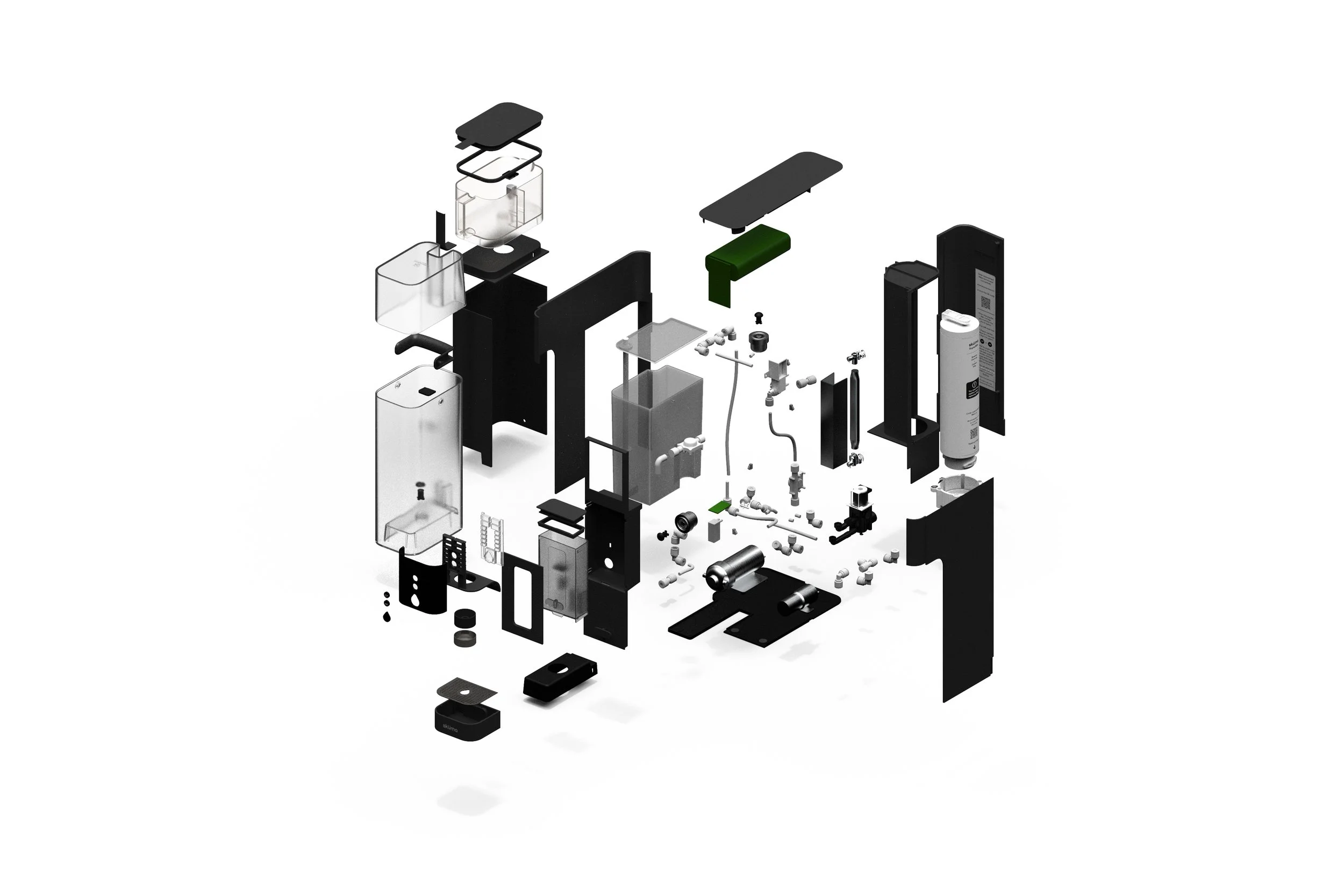

Part Count & Assembly

Reducing:

Number of components

Assembly steps

Risk of misassembly

This improves reliability and lowers cost.

Tooling & Production Volume

Design decisions differ for:

Low-volume production

High-volume mass manufacture

DFM ensures the product suits the intended scale.

DFM Is Not “Design Compromise”

A common misconception is that DFM reduces design quality.

In reality:

Good DFM improves product quality

Well-considered constraints lead to better outcomes

Manufacturable products launch faster and perform better

The best products are shaped by constraints, not limited by them.

DFM and Industrial Design Must Work Together

DFM works best when:

Industrial designers

Engineers

Manufacturers

are aligned early.

Separating these disciplines often leads to late-stage compromises that hurt usability or appearance.

FAQs – Design for Manufacture

What does DFM mean in product design?

DFM stands for Design for Manufacture. It means designing products so they can be produced efficiently, reliably, and at scale.

When should DFM be applied?

DFM should be applied early — during concept and detailed design — not just before production.

Is DFM only relevant for mass production?

No. DFM is important for low, medium, and high-volume manufacturing, although the considerations change with scale.

Does DFM limit creativity?

No. Good DFM improves outcomes by shaping design decisions around real-world constraints.

Can DFM reduce product cost?

Yes. DFM often reduces cost by simplifying parts, assembly, and tooling requirements.